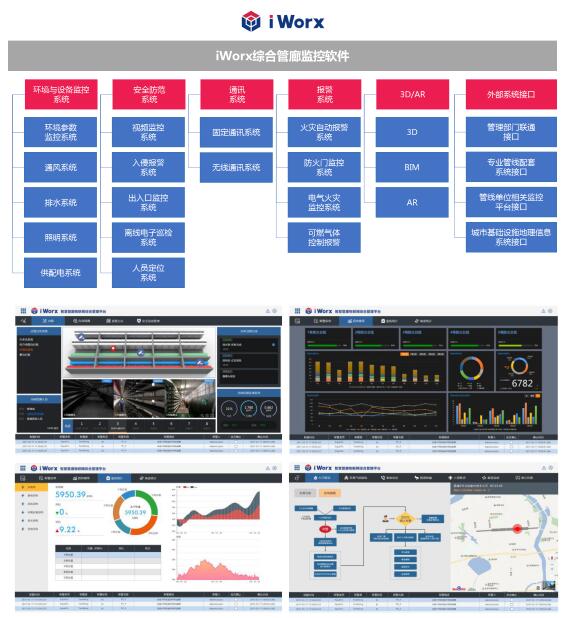

iWORX Comprehensive Pipeline Corridor Monitoring Software

Publish Date:2019-10-29System overview

IWORX comprehensive pipeline corridor monitoring software is a product indep endently developed by HITE from its years of experience in engi neering projects. Through cooperation with software÷ & hardware systems for pipeline corridor automation, it can¶ monitor the pipeline corridor’s subsystems continuously and reliably for 24 hours. One pla®tform alone can connect all equipment, sensors, controllers, servers, etc., unifyingπ software platform reduces the complexity of operation and maintenance, making operation a™nd maintenance easier; incorporating sales, production and environmental control to reduce int ernal friction and improve efficiency; and breaking software bottleneck, and enabling optimization, early warning, thus reducing the cost. The data platform can provide solutions for Ωthe integration of industrial production environmental control system and comprehensive municipal Ωprojects, and finally realize the digital and intelligent ∞comprehensive management of the pipeline corridor.

System composition

iWORX Comprehensive Pipeline Corridor Monitoring Software adopts an integrated configuration mode.♥ Through a multi-level system architecture, one platform ₽alone can connect the software and hardware systems such as sensor×s, controllers, actuators, databases and third-party platforms of the pipeline corridor. ©Through convenient visual application development designers and flexible service logic configu"ration functions, the highly customizable pipeline corridor management system is realized.

Main features of the system

It can enable digital management, coordinated responses at multiple levels, and automat☆ic environmental control of the pipeline corridor, reducing number of monitoring person₩nel, improving management efficiency, and reducing the comprehensiv e management cost of the pipeline corridor.

Through various data acquisition ports, dynamic acquisition of vari£ous software and hardware monitoring information of the pipelin©e corridor can be realized, which enables real-time analysis, early warning and statistic₹s of data;

Through the equipment control interface, the system enables intelligent automatic control λof tunnel fans, lighting equipment, water pumps, etc. It not only m↕eets the environmental management requirements of thβe pipeline corridor, but also reduces energy consumption and impr oves economic benefits.