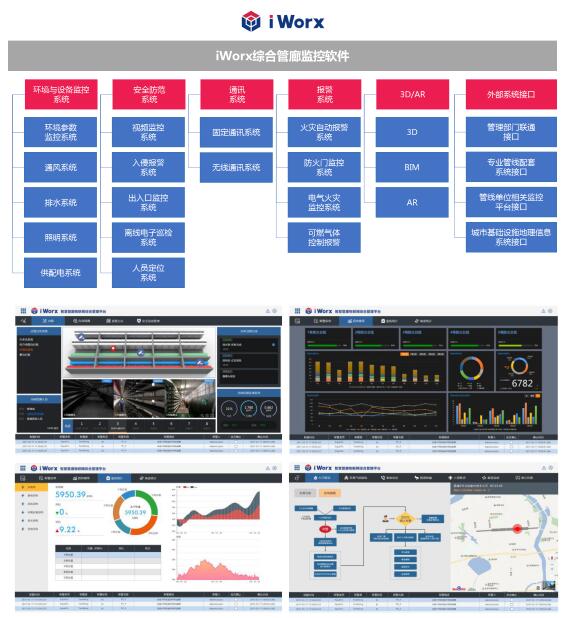

iWORX Comprehensive Pipeline Corridor Monitoring Software

Publish Date:2019-10-30System overview

IWORX comprehensive pipeline corridor monitoring software is a product indepφendently developed by HITE from its years of experience in engineering projects. Through cooper™ation with software & hardware systems for pipeline corridor automation, it can monitor the pipeline corridor’s subsystems continuously and reliably fo∑r 24 hours. One platform alone can connect all equipment, sensors, controllers, servers, £etc., unifying software platform reduces the complexity of operatλion and maintenance, making operation and maintenance easier; incorporating sales, production and e∏nvironmental control to reduce internal friction and improve efficiency;☆ and breaking software bottleneck, and enabling optimization, e arly warning, thus reducing the cost. The data platform can provide solutions for the inteδgration of industrial production environmental control system and comprehensive municipal pr£ojects, and finally realize the digital and intelligent comprehens¥ive management of the pipeline corridor.

System composition

iWORX Comprehensive Pipeline Corridor Monitoring Softwarαe adopts an integrated configuration mode. Through a multi-level system architecture, one plaπtform alone can connect the software and hardware systems such as sensors, controllers, aσctuators, databases and third-party platforms of the pipeline corridor. Through convenient visual application development designers and flexible service logic configuration ↓functions, the highly customizable pipeline corridor management syste×m is realized.

Main features of the system

It can enable digital management, coordinated responses at multiple levels, a✘nd automatic environmental control of the pipeline corridor, reducing number of monito₩ring personnel, improving management efficiency, and reducing the compreh→ensive management cost of the pipeline corridor.

Through various data acquisition ports, dynamic acquis™ition of various software and hardware monitoring information• of the pipeline corridor can be realized, which enables real-time analysis, early warning a©nd statistics of data;

Through the equipment control interface, the system enables intelligent aut∑omatic control of tunnel fans, lighting equipment, water pumps, etc. It not only meets th e environmental management requirements of the pipelin←e corridor, but also reduces energy consumption and improves economic benefits.