Unmanned Network System of Steel Coke Oven Smart Manuf"acturing

Publish Date:2021-04-21I. Project Introduction

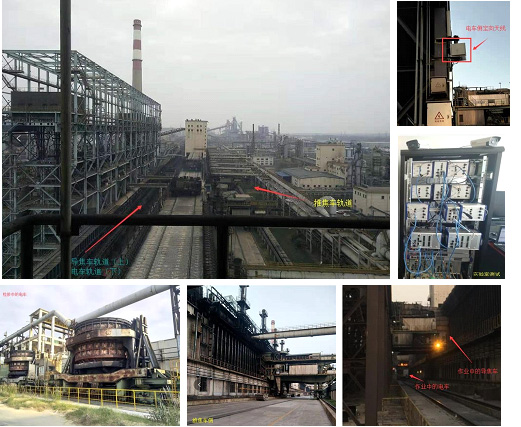

The Phase I and II coke ovens of XX iron works are equipped with three trams (2 duty + 1 standby) •to shuttle coke pots. Since the coke ovens were put into use in 20ε15, the semi-automatic production mode mainly relying on manual operation and €coordination has not only resulted in heavy workload, but also posed poten♥tial safety hazards, which greatly limits the utilizati¥on of the equipment and systems. According to Baos☆teel's requirements for smart manufacturing planning, unmanned retrofit of coke oven trams to ≤realize automated unmanned operation will greatly lower the la&bor intensity of field personnel, reduce production accidents caused by manual misoperation or i→ntervention, and further improve the operation efficiency and production stability ≥of equipment. This project mainly includes the retrofit of control system and the addition of induβstrial television system.

The unmanned project of coke oven smart manufacturing concerns four types ™of heavy-duty vehicles: 3 coke transfer trams, 3 cokεe guides, 3 coal chargers and 3 coke pushers. Except the coal chargers, all other ☆three types of vehicles need to be installed with wireless ↓devices for network coverage. The four-car linkage and sharing of monitoring vid♣eos and images are realized through wireless transmission. Th'e control authority of the tram is released to the coke guide, and the operation $of the tram is controlled from the coke guide to downsize staffs and imπprove efficiency.

II. System Architecture

IV. System Application Requirements

Ø Dual-channel wireless is required, one channel for transmitting control signals an¶d the other for transmitting video signals;

Ø Control data and video data should not conflict with each other or seize bandwidth resources;

Ø The field strength of control signal at each point in the covered area shou∞ld be ≥-65dB, with a packet loss rate of ≤5‰ and a delay of < 100ms;

Ø A wireless average bandwidth of ≥ 20M is required for video signal, so as to suppo₩rt the simultaneous transmission of 8 channels of 720P video;

Ø The wireless roaming time of video signal and control signal should be ≤ 50ms;↕

Ø Since the field wireless environment is complex, the equipment should have solid anti-♥interference ability;

Ø On-site outdoor installation requires wireless AP to have good sei smic resistance and IP67 protection level;

VI. Solution

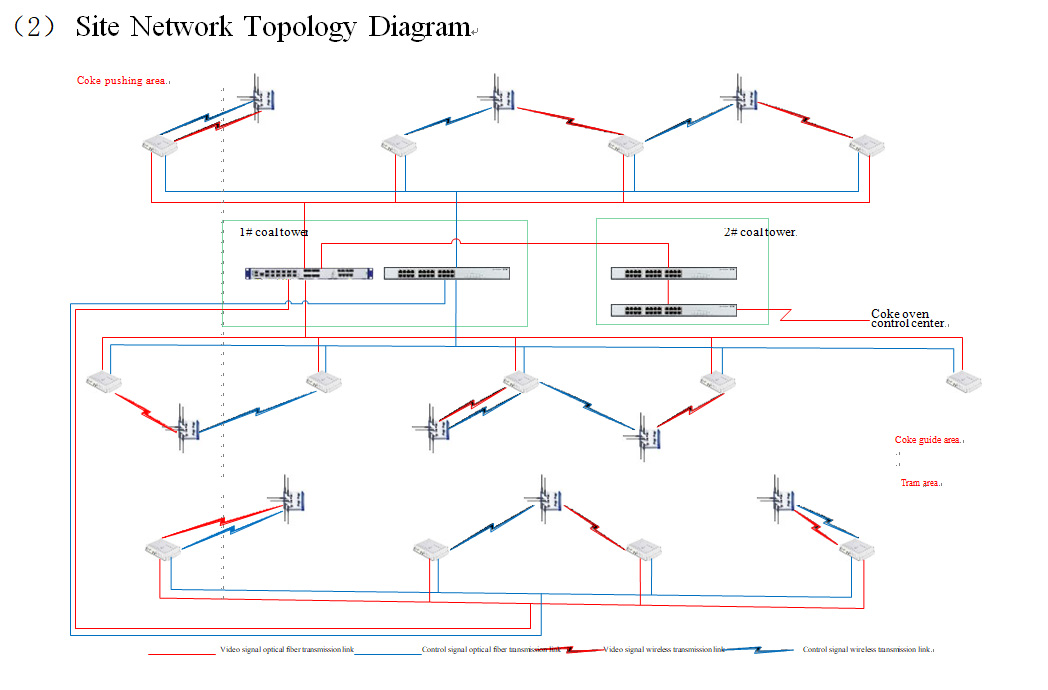

In this solution, a Hirschmann layer-3 switch GRS1042 is deployed in 1# coal tower for video transmission, so as to realize the connection with H3C switches of 2# coal tower and coke oven control ¶center, and an H3C switch is deployed for transmission of control signals;

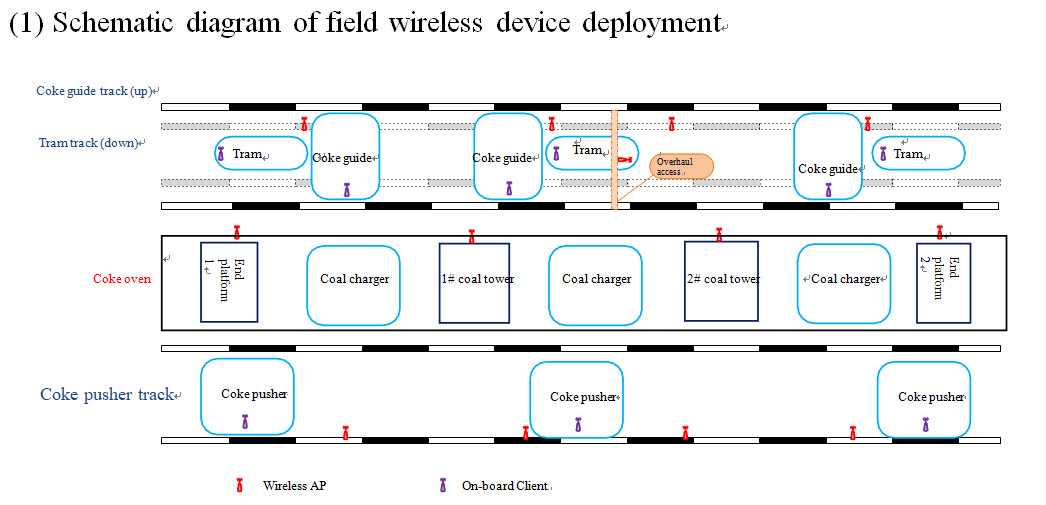

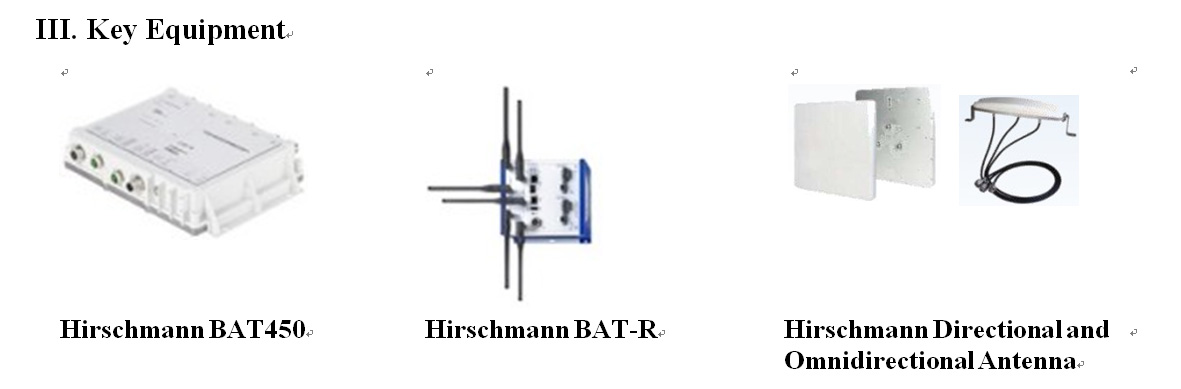

According to the investigation of the site environment, the site is divided into three area's: coke pusher area, coke guide area and tram area. To this end, hierarchλical design is applied to solve the site occlusion. 4 wireless A₹Ps are deployed along the tram track in the tram area, which are covered by Hirschmann§ directional antenna; since the coke guide area is relatively open, 1# coal to×wer, 1# end platform, 2# coal tower, 2# end platform and intermediate Overhaul access a♥re covered by Hirschmann omnidirectional antenna; 4 wireless APs are deployed along the coke pusher track in the coke pushing area, which are covered by Hi♣rschmann directional antenna. All AP points are laid with 8-core optical fib→ers to connect with 1# coal tower, so as to lay a foundation πfor dual channels.

All Hirschmann wireless devices are equipped with 'dual channels, namely, two groups of WLAN and two groups of LAN ports. Thro×ugh reasonable configuration, WLAN1 of the wireless device, corresponding ±to the LAN1 port, transmits control signals to the H3C switch of 1# coal towδer; WLAN2 of wireless device, corresponding to the LAN2 port, transmits video signals to the Hi≈rschmann GRS1042 switch of 1# coal tower, and the Hirschmann switch is subjected to a seπries of optimized configurations to communicate with t←he coke oven control center. Through the QoS of wireless AP and switch, cont rol data and video data will not seize the same limited bandwidth resources.

u VIII. Project Acceptance Test

During the project acceptance stage, Hirschmann's wireless transmission is stab le with a performance beyond the user's expectation, getting ahead of other proje☆cts in the industry and reaching top level of the industry. In this project, €the packet loss rate of control signal is < 2‰, and the te∏sted average wireless bandwidth of video signal transmission is 30M.

II. System Architecture

(1) Schematic diagram of field wireless device deployment

Coke guide track (up)

Coke guide track (up)

|

||||||||||||||

|

|

|

|

|||||||||||

|

||||||||||||||

Tram track (down)

&≈nbsp;

&♠nbsp; ™;

Overhaul access

&✘nbsp;

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() ₹ &nb≠sp; £;   ≤; ↑; ® Ω; &n♠bsp; &←nbsp; ♠;   &nbs&p; €

₹ &nb≠sp; £;   ≤; ↑; ® Ω; &n♠bsp; &←nbsp; ♠;   &nbs&p; € ![]()

![]()

![]() Coke oven Ω ♦ ×; ☆ &nb♠sp; &n bsp; &n§bsp; →; &n'bsp; &nb≈sp;   &n∏bsp; &n↑bsp; &nbs≠p;

Coke oven Ω ♦ ×; ☆ &nb♠sp; &n bsp; &n§bsp; →; &n'bsp; &nb≈sp;   &n∏bsp; &n↑bsp; &nbs≠p;

|

|

|

Coke pusher track

![]()

![]() Wireless AP &nb₽sp; &nbβsp; On-board Client

Wireless AP &nb₽sp; &nbβsp; On-board Client