Industrial Network Scheme of in Cigarette Factory

Publish Date:2021-04-21I. Project Introduction

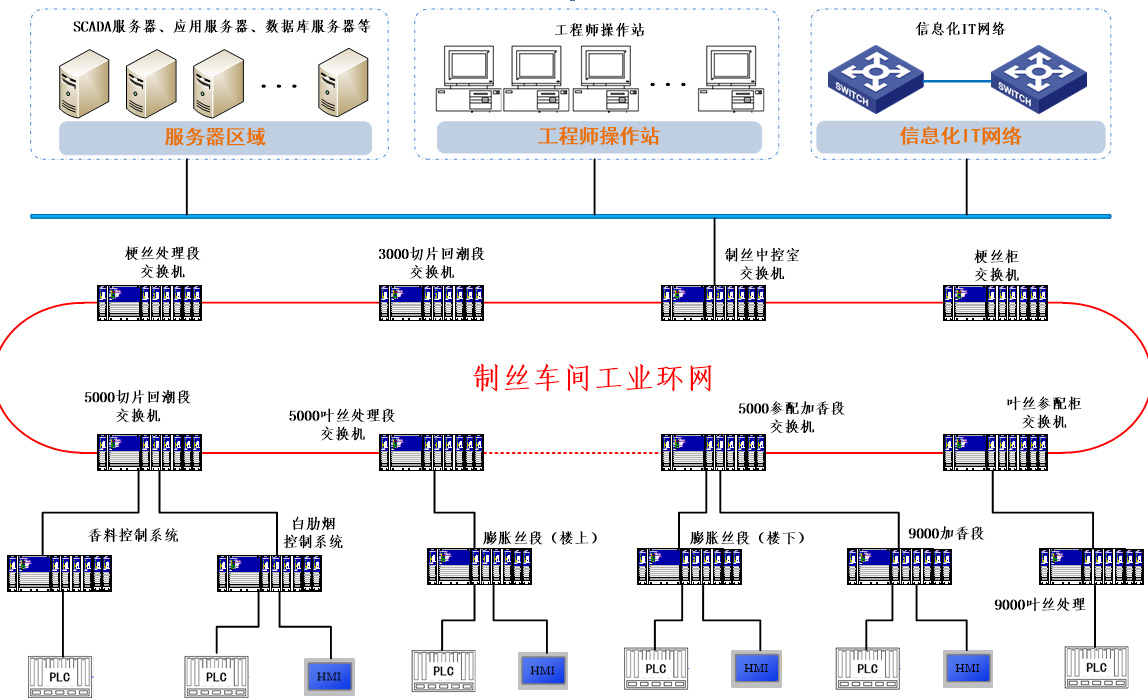

The backbone network of tobacco shredding workshop in XX Ci garette Factory was built in 2009. The industrial con$trol network system of tobacco shredding workshop is the bridge among equipmen™t control system, production management system and production co≈ntrol system. With I/O server as the core, the system connects the main co♦ntrol PLC of each production line of tobacco shredding workshop, each conσtrol section and the main control PLC of stand-alone control system ♦with I/O server through industrial Ethernet, so as to realize convenient and quick data e xchange. The I/O server then provides the collected data to workshop database server, >supervisory computer and field operation query terminal for centralized monitoring and information query.

Tobacco shredding is the first working procedure of production <and processing in cigarette factory, which involves 40 proce♦sses and 120 indicators. Moreover, the tobacco shredding workshop has< the characteristics of wide processing area, various equipment and difficλult control. Therefore, the network adopts Ethernet transmission wit¶h good openness and wide application, so as to transmit various data collec÷ted on site to the server. In order to ensure the reliability of the network, the ring $network is adopted as the framework of the workshop backbone network.

II. System Architecture

III. Key Equipment

IV. System Requirements

u According to the communication requirements of® network sites, the system adopts ring network architecture. Any failure of any physical lin✘k in the ring network will not affect the stable transmission of the system;

u Ring network self-recovery time < 50ms;;

u The network adopts 1000M uplink and 100M access "to ensure the requirements are satisfied;

u The network is designed according to the concepts of advancement, feasibility, security and reliability, and is upward compatible;

u The equipment adopts fanless design, DIN rail installation• and modular switch. Each module supports hot plugging λfor easy extension, and 20% of the ports are reserved;

u The switch supports multiple management modes, φand the configuration and maintenance interface is simple and easy to operate;

u Network management software is used to monitor and manage th→e whole network. The interface of network management software must be simple and usγer-friendly, and support visualized management and automatic generation of topology and various f≠ault alarms.

V. Solution

A Hirschmann MS4128 rail-type modular switch is deployed respeαctively at the convergence points in tobacco shredding central control room, stem shred ←cabinet, leaf shred blending cabinet, 5000 blending and flavoring section, 5000 leaf shred pro$cessing section, 5000 cutting and damping section, stem shred processing section, and 3000 slic↑e cutting and damping section. The switches are connected end to end through 1000M ports to fo≠rm a 1000M industrial Ethernet transmission ring network. The sp₹ice control system access switch, burley tobacco control system acces≠s switch, expanded tobacco section access switch, 9000 flavoring sectσion access switch and 9000 tobacco shred processing access switch are ☆linearly connected to the industrial ring network nearby. A set of Hirschmann Hivision networ✘k management software is deployed in the central control room to€ realize real-time monitoring of the network.

Reasonable configuration is carried out on the 1000M industrial ring ne↓twork switches and access switches of tobacco shredding workshop, so that the main cont÷rol PLC of each production line, each control section and the main contr®ol PLC of stand-alone control system and I/O server can realize convenient and quick data exchang₩e, and meet the construction requirements.

&nb±sp; §; ↑;

Rail modular switch Rail modular switch ∑;

MS4128 &n€bsp; MS30