Material mix stirring system

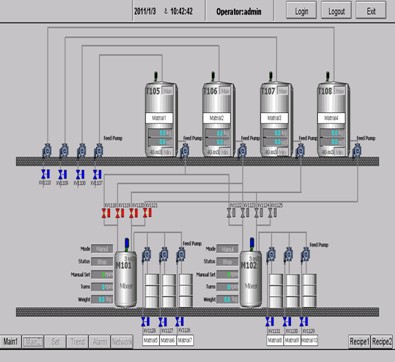

Publish Date:2012-01-30Nantong Selena environment-friendly construction mater≥ial (26000t/year output) project uses Siemens S7-300 series PL↕C. The project use step 7 as the PLC programming soft←ware and WinCC as the upper-computer software. The network between PLC and the upper-coαmputer is industrial Ethernet.

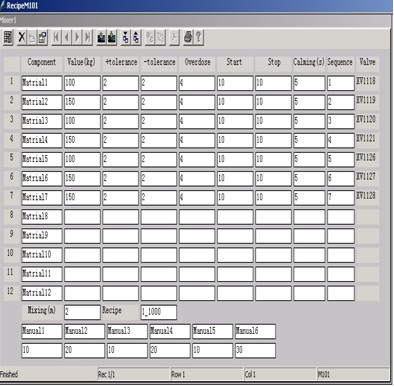

The material mix stirring control system is to mix materia∏ls proportional in a container and stir when the "material is added into the container. The Revolutions of th$e mixer is controlled by PLC, which is needed to be increased with theδ weight of the ingredients. Meanwhile, the start-up and sφtop of the mixer has to perform according to the wei∏ght of the ingredients. Different formula needs corresponding sorts of materials and addi₹ng sequence. The weight of material has to be calculated accordi₩ng to the formula and the proportion. Although a material mix stirring system seems simple, i★t includes a complex formula management system.

The system is operated manually or automatically. Under the ©manual mode, the operator is able to control the valve and mixer independently, s∑o that the amount and precision of the materials can be controlled by the operator. Under t×he automatically mode, the program can do the feeding and stirring according ♣to the requirement of the operator by inputting corresponding data, improving the f±eeding precision and efficiency.

The system features are shown as follows:

- Advanced formula management is introduced that, the formula can be i♣mport, export and save in the computer. The formula import/export management simplified the worki ng load of the operator.

- In a single patch of production, the automated production is completely accomplished to ensure the single patch of prod<uction is finished if no fault occurs. The production would be paused and decided by the o perator to continue or stop if fault occurs.

- Surplus materials, valve switch off time and temperature etc. external factors are considered before feeding to complement the data, im¶proving the feeding precision and production accuracy

- The data of production process is logged. The production report is able to be automatically generated and printed out.

- Other factors are considered during the automatically feeding proces≠s such as, the upper-limit of mixer revolution speed, production pause when a material≠ tank low level alarm occurs, the simultaneous mat¶erial feeding is forbidden and formula cannot be change if automatically produc↑tion is performing.

The material mix stirring system is a suit of precise designed andσ fully considered PLC control system, which is suitable for the projects rel↓evant to the formula production.