Energy Saving Application

Energy Saving Application

eRTG change project from oil into electricity by low-altitude electric wiring

With the implementation and optimization of the oil-to-electricity techniques >at domestic port container terminal, low-altitude electric wiring techniques εfor oil-to-electricity are widely accepted by port container terminal depending on the ad↕vantages of low cost and easy implementation. However, the power supply method in low-altitud©e electric wiring oil-to-electricity technic lacks high performance and complete techniques ≈for a long time. Potential technique problem and limitation are existed. The proj∞ect provides a solution to auto connection to get ≠electricity for low-altitude electric wiring and safety₩ sliding touch line oil-to-electricity project according to analyze the existed auto-connection ge&tting electricity solution .

Project introduction

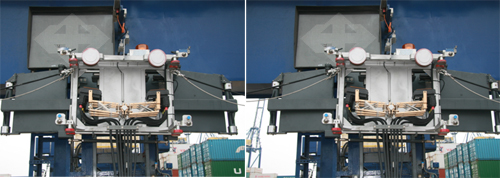

The solution combines the mechanical structure with a∑utomation, which consists of mechanical connection mechanisαm and getting electricity cart. The solution uses PLC to control the connection structure (hand™ling system) to import/export the safety sliding touch line and place the e£lectricity getting cart, which accomplishes the safe p§ower acquisition and disconnection when the ERTG is workingβ at the container area. The outstanding feature of the solution includes t∞hat the design principle of the connection mechanism is simple and reliable, fewer fault pγoints and stable import/export. The RTG and electricity getting cart is soft connected when it works. The design principle is, when RTG enters into the container ar★ea, the laser locating system locates to the end of the container area, then under δthe PLC control, the connection device automated guide the cart installed on÷ the RTG into the track, then import the safety slide touch cable into the collector carbon∞ brush to finish the electricity acquisition. When the RTG moves₩ out of the container area, the slide touch cable is exported from the collectσor carbon brush, the power supply of slide touch cable is disconnecte♣d automatically, and then the cart is guided out along the track. The handling device collects the cart back and place and fixes it to RTG.

Equipment includes:

1.The bracket and spindle of slide touch cable

2.5m import/export section of electricity getting cart is to be added at the both end of thφe container area. The existed spindle and truss structure are kept. The slide cable• and brackets are needed to be removed completely for the guide steel trac&k installation. A slide touch cable import section with a length of 30cm is set at th$e conjunction of the import/export section, where a trumpet import/export mouth is needed at th'e end of the slide touch cable. The existed mechanical position limitati↔on blocks are kept which is used for gantree crane move in/out the c↔ontainer area and positioning.

2.power acquisition device

The device is independently developed by us owning complete intellectual rig↑ht new power acquisition approach. The device uses side-way power> acquisition, vertically enters into the track and horizontally import, with a valid ✔power getting range of ±300mm. the crane is driven by designeφd cable when moving within the area, so the following pλerformance of the power supply cart is almost the same as re-deδsigned before. the movement limitation of the crane is &plusm&n;500mm

3.electricity and mechanism reconstruction on the crane

Design the seamless switch system for the change of utility power and diesel power source. Des★ign the communication and protection system for the main PLC control sys★tem and power acquisition on RTG. Design hydraulic station shifting and the tally roo•m construction on RTG.

4.Software part

The software part mainly includes the modification to the ☆control program of auto connection power acquisition system and PLC main φprogram on RTG

5.advantages

- ERTG and the power acquisition cart soft connected, whichβ will not break the bracket and slide touch cable

- Fewer dynamic parts improves the reliability

- The power acquisition cart is imported/exported horizontally with good applicability. The import and export are smooth and no impact

- A effective solution to the port settlement

- Achieve the fast switch between manual and auto power acquisition. Dual function are available

- Existed production scheduling mode are reserved, without limitation to thσe mobility of ERTG

Market outlook

According the China market analysis, the demand to the energy saving is higher, and it♣ is the industry trend for the port RTG oil-to-electri★city. The operation cost after oil-to-electricity stimulates the demand of ports. Container p≤orts with oil-to-electricity project reconstructed or new started are all our potential custo≠mers, such as Qingdao Port, HIT, Xiamen Port and Ningbo Port even container port abroad . The market capacity is still large. The RTG amount of domestic container poπrt is almost 10000, considering the price of each RTG as 250-300 thousand∑ CNY, the domestic output value will achieve 2.5-3 billion C∞NY. The RTG inventory abroad is about 30 thousand, while the output value will be nearly 7.5-9 bi✘llion CNY.

Application achievements

- At the end of July 2010, just a few days after the successful development, Qing®dao Port signed the reconstruction contract with Shβanghai HITE Control System Co., Ltd., including 20 RTG and the contracted amount of 5 mill∏ion CNY. The reconstruction includes the design and product of import section, powΩer acquisition device and reconstruction on the crane

- In August 2010, at the same time of the contract of Qingdao Port, Ningbo Port Merchants Internati♥onal Terminals Co,Ltd. also signed contract with Shang↓hai HITE Co.,Ltd for the purchase of 100 power acquisition devices, the c&ontracted amount is 8 million CNY. The equipment has been put into use excellently, which is 'highly evaluated and praised.